A bi-directional static load test (BDSLT) is a method used to internally load a deep foundation element from specific points along its embedded length. The load is applied using a jack assembly of YJACK360 or OJACK360. This setup allows the jack to exert an upward force against the shaft resistance above the jack assembly and a downward force against the combined shaft resistance below the assembly and the toe or base resistance. The deep foundation element is equipped with instruments to measure shaft and toe movements, as well as soil resistance to the applied load. YJACK360 and OJACK360 cells are suitable for installation in drilled shafts, augercast piles, drilled displacement piles, slurry wall panels, and barrettes.

For a comprehensive overview of bi-directional static load testing, please view the animation below.

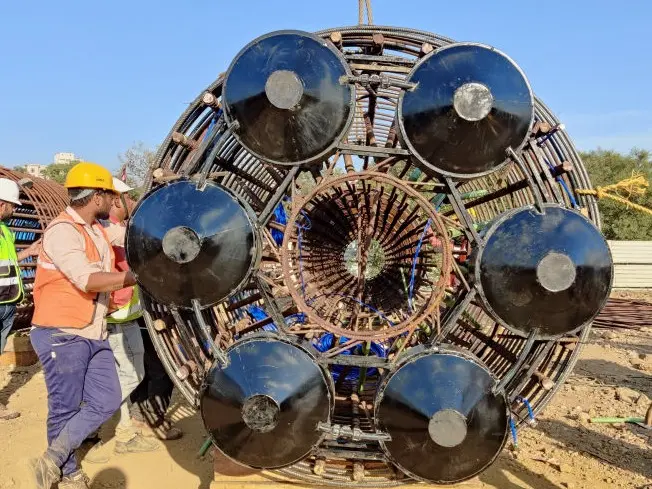

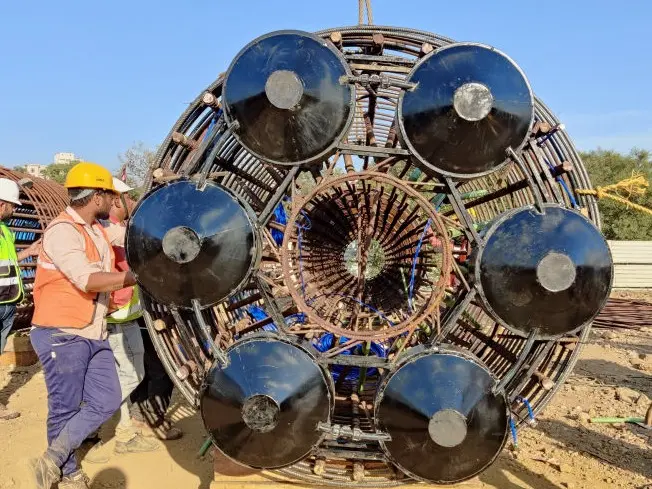

In drilled shafts, it is crucial to configure the jack assembly to accommodate the cells, as well as to properly position the tremie pipe or pump line for effective concrete placement. Below are generalized plan and elevation views of single and multiple YJACK360 and OJACK360 jack assemblies to illustrate these considerations.

Bi-Directional Static Load Testing (BDSLT) is regulated by ASTM D8169 – Standard Test Methods for deep foundations under Bi-Directional Static Axial Compressive Load.

Our BDPLT test employs MrGeo - Static Compressive Pile Load Tester - 12 Channel, an advanced technology providing substantial benefits to stakeholders in the pile testing industry.

Static Compressive Pile Load Tester (SCPLT) is a state-of-the-art testing equipment to perform static load test on deep foundation piles. This automation system is to record applied load (Q) vs pile displacement (D) in static load test for static compressive (SC), static tensile (ST) and static lateral tests (SL).

For those seeking more detailed insights into pile testing methodologies, we invite you to explore the specialized services offered by GeoAli.